Ensuring food quality by testing for the presence of spoilage organisms that can impact shelf-life, render a product inedible, or halt production, requires constant vigilance. However, the repetitive nature of microbiology quality control (QC) testing of food, beverages, and ingredients can make tedious work of this important analysis that keeps our food supply safe and delicious.

The membrane filtration (MF) technique is a well-accepted reliable method for fast, flexible testing, whether testing materials with concentrated or very low levels of microbes. The technique was introduced in the late 1950s as an alternative to the most probable number (MPN) procedure for microbiological analysis of water samples. The MF technique offers the advantage of isolating discrete colonies of bacteria, whereas the MPN procedure only indicates the presence or absence of an approximate number or organisms (indicated by turbidity in test tubes).

Advantages of the membrane filter technique include:

- Permits testing of large sample volumes

- Reduces preparation time as compared to many traditional methods

- Allows isolation and enumeration of discrete colonies of bacteria

- Provides presence or absence information within 24 hours

- Allows for removal of bacteriostatic or cidal agents that would not be removed in pour plate, spread plate, or MPN techniques

The MF technique can be performed by utilizing different laboratory workflows which may implement reusable hardware, partially disposable products, or individual disposable funnels. When selecting the best workflow approach and choosing microbiology products, maximizing both efficiency and controlling contamination are paramount.

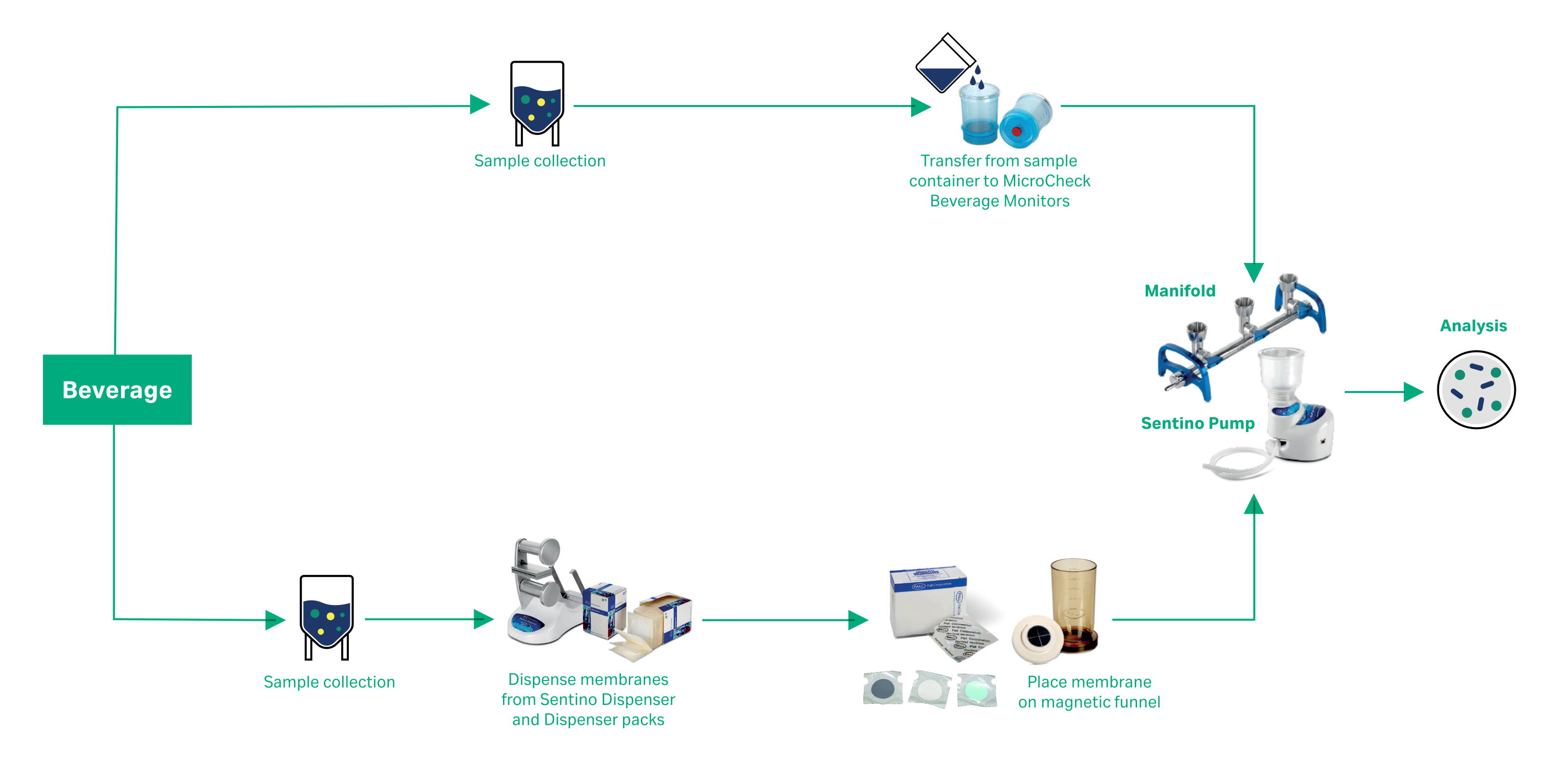

Fig 1. Microbiology workflow approaches using Cytiva products.

It is important to select high-performance products with ergonomics that reduce long-term injury risk. This is especially beneficial in busy laboratories that handle numerous samples on a daily basis.

The repetitive nature of routine laboratory work puts microbiologists at risk for repetitive strain injuries (RSI). Routine activities often include repeating the same movements over and over, which can take a toll on hands, wrists, and shoulders and can lead to serious injury. RSI can lead to laboratory user fatigue and variability that causes poor technique, errors, and increase cross-contamination. In a microbiology laboratory, there are many ways to avoid manual labor stress by working in a more ergonomic manner. Choosing the right tools can make all the difference.

Creating filtration tools that are designed to make your daily food and beverage QC work easier is at the top of our mind when we explore new products. We offer a suite of funnels, membranes, and equipment that is designed to be flexible for different testing workflows.

MicroCheck™ II Beverage Monitors (Pall™ Life Sciences products)

Our Microcheck II Beverage Monitor can be used to analyze contamination in samples, helping to identify potential problems before they leave the lab. The disposable, gamma-irradiated filter funnels come ready-to-use, fully assembled, with both filter membrane and funnel. They are delivered in a sterile bulk pack of 50 units and are not individually packaged, which allows for rapid use in the busy high-throughput testing environments, such as beverage microbiology quality control labs.

Featuring a convenient and ready-to-use design, these disposable filter funnels can help increase the productivity and efficiency of laboratories that do not have time to clean and sterilize reusable hardware. The funnels feature an easy-to-use design; a unique squeeze separation of the cylinder from the base allows easy access to membrane. Alternatively, the lid of the funnel can be used to convert the base of the funnel into a Petri dish, which allows for the sample culturing without removing the membrane.

MicroCheck™ II Beverage Monitors.

- Finished product testing of beverages for microbial contamination prior to release

- Available with 0.45 µm and 0.8 µm, in either white or black membranes, to allow the easy identification of light-colored organisms

- Evaluate raw materials such as syrups, flavorings, water, and other liquid additives for microbial content

Microbiology manifold and Sentino™ Pump (Pall™ Life Sciences products)

We provide microbiology manifolds and pumps that can be used in tandem with our Microcheck™ II Beverage Monitor products or alternatively they can be used with separate membranes and reusable funnels.

Our microbiology manifold allows you to optimize testing without sacrificing cleanliness.

- Requires no tools or tape to put together

- Disassembles easily for thorough cleaning

- Inlet and outlet can be set up at either end of the manifold, avoiding the risk of contamination due to reaching over the top of funnels to turn on and off valves

The manifolds are available in a 3-place format, which can easily be coupled together to form a 6-place manifold. The modular design allows for easy separation for disinfection and/or sterilization.

Microbiology Manifold

Coupled Microbiology Manifolds.

The Sentino Pump streamlines analysis by replacing the traditional vacuum filtration system with a small peristaltic-action pump that draws samples through the MicroCheck units. The filtrate is channeled directly to drain or waste collection through a disposable fluid path. The fluid path is simple to load and completely disposable to eliminate potential biofilm build-up. There is no need to clean, wrap, and autoclave a bulky multi-place manifold. The potential for sporadic and unnecessary contamination is removed.

The unit’s compact design and its ability to be operated by a self-contained rechargeable battery means that it’s easy to use in confined spaces and it frees valuable benchtop space, providing flexibility in arranging workspace for optimal efficiency and workflow.

A soft-touch keypad featuring simple on/off and pulse functions makes it easy to operate, with no complicated programming to validate. Operating parameters are preset and fixed to meet the published requirements for membrane filtration (MF) technique as described in ISO and ASTM methods, thereby eliminating the need for extensive validations.

Sentino™ Pump

Sentino™ filter funnels and magnetic funnels (Pall™ Life Sciences products)

Laboratory budgets also need to be considered when selecting products for use in microbiology workflows. For microbiologists wishing to adopt either a partially disposable or reusable disposable product workflow Cytiva offers a range of membrane discs and funnels.

Sentino funnels are available in both 100 mL and 250 mL volume formats, they are gamma irradiated eliminating the need for autoclaving or any other cleaning/sanitizing techniques. The base of the funnel adapts for use with Sentino pump or microbiology manifold.

Cytiva microbiology products

Our patented magnetic filter funnels feature a unique magnetic closure action that facilitates a simple one-handed operation, while ensuring there is no risk of membrane disk ripping or tearing that can occur with screw fitting funnels. These reusable funnels feature a sturdy plastic construction that is shatterproof and can withstand multiple autoclave cycles. The 47 mm magnetic filter funnels are available in 300 mL and 150 mL sizes for an easy fit into autoclaves. For larger volume samples a 500 mL size is available.

Culturing sensitive organisms can be difficult, and identification is critical for process control and public safety. Analysis membranes must be manufactured to the highest standards for accurate microbial growth and recovery.

We supply membrane disc filters that can be used with both Sentino filter funnels and our magnetic filter funnels. Membranes are available in either individual packs or dispenser packs. Dispenser packs are available for use on our Sentino filter dispenser or the eButler membrane dispenser.

Our membranes include the mixed cellulose ester GN Metricel™ membrane, available in a 0.45 µm pore size, and the Supor™ 200 PES membrane, available in a 0.2 µm pore size.

We also supply a number of membranes for specific testing such as green and black membranes of larger pore sizes for yeast and mold analysis.