Commercial Aircraft Filtration

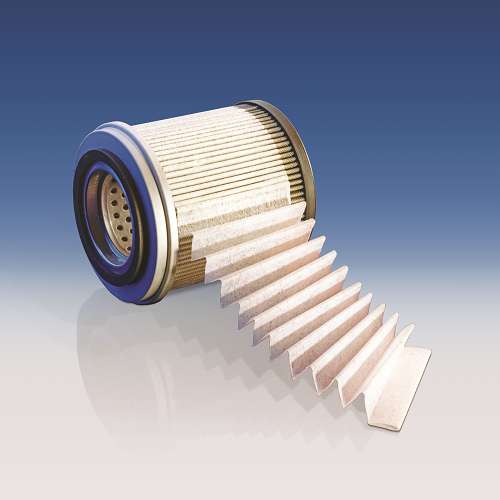

Expertly engineered contamination control solutions for aircraft fluid systems

The Importance of Reliable Filtration Systems in Commercial Aviation

From cabin air to Nitrogen Generating Systems (NGS) or hydraulic flight control systems, we have decades of experience in designing and manufacturing contamination control solutions for your aircraft fluid systems. We work closely with aircraft and system component Original Equipment Manufacturers (OEMs) to ensure that our commercial aircraft filtration solutions meet or exceed stringent requirements demanded by the industry.

-

System Applications (ATA chapter)

-

Aircraft Platform

-

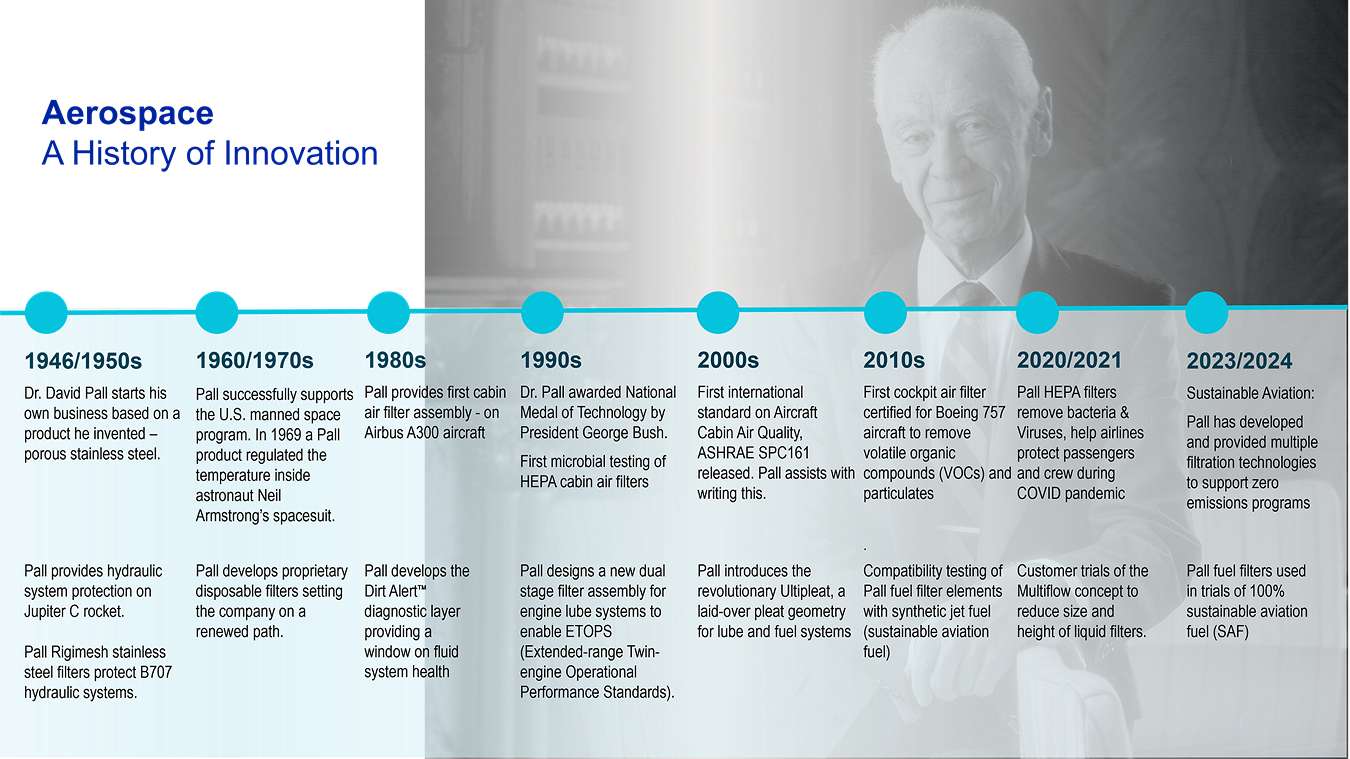

Innovations in Commercial Aircraft

-

Sustainable Solutions

Decades of expertise and experience, means that Pall has the largest and broadest portfolio of OEM approved, commercial aircraft filtration products.

Pall filtration solutions are approved and used on a wide range of commercial aircraft programs including, but not limited to:

- Airbus A220, A300/310, A320 family, A330/340, A380

- ATR42/72

- Boeing B737 (classics and NG), B747, B757, N767, B777, B787

- Bombardier Challenger, Dash8, Q400

- Embraer EMB110, EMB120

- Fokker 70, 100

- SAAB 340, 2000

We also provide high performance filters for the engines that power these aircraft. Read more about Pall’s engine lube and fuel filters

For price and availability for a specific aircraft Part Number (PN), please contact our authorized commercial airline distributor, Satair.

For any technical questions, please contact us:

Pall stands committed and uniquely positioned to support the aviation industry's transition to sustainability. We partner with Aerospace OEMs worldwide, guiding them through the often-challenging requirements of this transformation. We focus on designing, manufacturing, and supporting the certification of a wide range of flexible, efficient, and lightweight filtration, separation, and purification solutions. These solutions enhance the performance and durability of critical systems and contribute to the industry's sustainability goals while always maintaining our commitment to safety.

Pall - Satair partnership

Satair are Pall’s exclusive distributor for all filtration products for the commercial aircraft aftermarket. Our two companies have been working together for over 30 years, having signed our first distribution agreement in 1991. Satair are currently the world's largest distributor of filtration products for the commercial aviation Industry and have an experienced aftermarket sales team to assist with all parts enquiries.

Want to buy a replacement Pall aircraft filter?

For airlines or MRO customers who want to purchase a spare part, please contact our authorized stocking distributor, Satair

OEM customers, if you have an aircraft application that needs a filtration solution, please talk to one of our experts Contact Aerospace

Technical innovation, custom design engineering and years of experience developing and deploying robust integrated filtration and separation equipment are the key elements that make Pall Aerospace a reliable partner in implementing contamination control solutions for your aircraft fluid systems

Pall contamination control solutions help to

- Improve critical system reliability and performance

- Extend the life of components

- Reduce maintenance costs

- Protect the on-board comfort of crews and passengers

Maintenance, Repair and Overhaul Services

We value our customers and understand their need for ongoing support so we provide them with a dedicated service network available for maintenance, repair and spare part logistics for all our products - before, during and beyond delivery of a solution. Every day.

For expert support with your commercial aircraft filtration requirements, contact us below.