Filtration Solutions for Helicopters

Mission ready contamination control solutions

Filtration solutions tailored to unique mission environment requirements

From engine intakes to the on-board electronic systems, our products help you protect your assets from contamination, ensuring complete reliability and mission readiness. Supported by our MRO services team, Pall helicopter solutions will help you improve critical system reliability and performance, dramatically reducing maintenance costs and expanding the life of components.

Featured Products

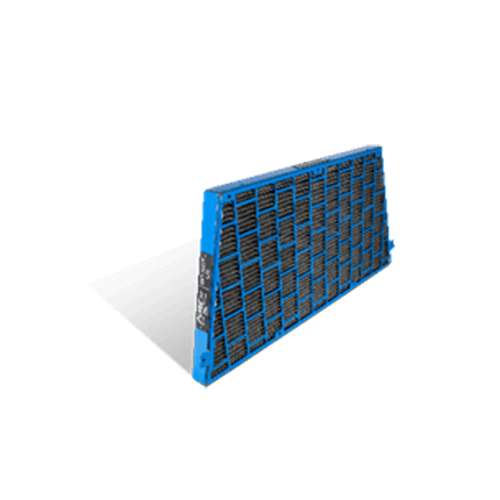

Engine Air Intake protection

- Protect your rotary wing platform engine from airborne threats with either a self-cleaning vortex system or a cleanable Inlet Barrier Filter

- Solution is designed to suit the operating environment

- Proven in military operations in brownout conditions

- 50+ helicopter air intake solutions

Hydraulic Control Systems

- Improve the operating reliability and performance of the helicopter hydraulic system components

- Extend service life of pumps and valves

- Significantly reduce maintenance costs

Gearbox Transmissions

Dual stage filter assemblies remove damaging particulate contamination from the helicopter transmission system and:

- Prevents component wear

- Improves reliability of pumps, gears, bearings

- Reduces maintenance costs

Engine Fuel and Lubrication Systems

Maintaining a specified level of fuel and lube cleanliness is critical to the operation and reliability of helicopter engines. Using fine filtration leads to:

- Improved system performance

- Increased component service life

- Reduced unplanned maintenance

Avionics (E/E) Cooling Systems

We provide robust avionics (electronic equipment) cooling filtration solutions that remove free water and solid particulates from cooling air, ensuring the reliability of essential helicopter electronic systems is maintained.

Fluid Recycling (Ground Support Equipment)

Purify helicopter hydraulic fluid by removing particulate, air, solvents and water. Extend the fluid’s service life and help the environment by using Pall’s NATO codified fluid portable purifier.

Better protection for demanding operations. Every Day.

Contamination of fluid systems and component parts is a significant threat to the operability of rotary wing aircraft. It compromises fluid integrity, and in turn, critical aircraft systems that can result in immediate and longer-term system failure or component damage. The challenges posed by contamination not only can ground helicopters, leading to costly maintenance, they can also result in catastrophic system failure, proving hazardous to safety of occupants.

The products manufactured by Pall Corporation meet the strictest industry regulations and are guaranteed to addresses main contamination control challenges in the helicopter market. With bespoke efficient solutions tailored to your needs, our filtration and separation technology protects systems and components, extending equipment life, reducing maintenance costs, improving performance, and keeping the highest standards of safety.

For more information on our portfolio of products, visit our product pages or contact a Pall Aerospace expert today.

PA100 PUREair System from Pall Aerospace

Pall PA120 Mi8 Mi17 Helicopter Vortex Engine Protection

Maintenance, Repair and Overhaul Services

We value our customers and understand their need for ongoing support so we provide them with a dedicated service network available for maintenance, repair and spare part logistics for all our products - before, during and beyond delivery of a solution. Every day.

Discover how to enhance critical system reliability and performance - get in touch below to speak with one of our filtration experts.