What is cannabis oil clarification?

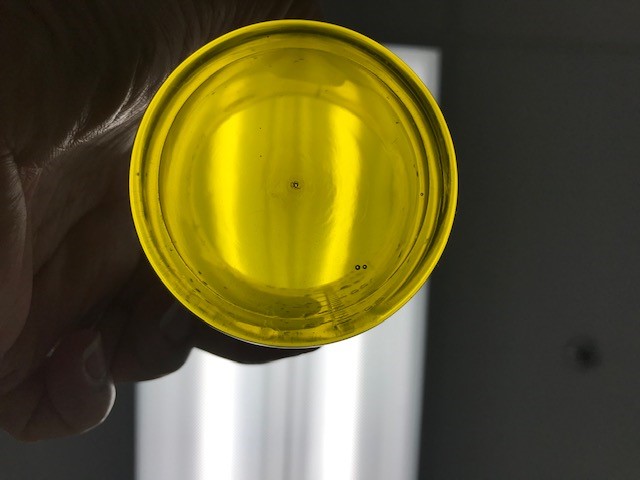

Clarifying cannabis oil is a key step in producing cannabis oil. Passing the cannabis extract through a filter system will remove unwanted waxes, fats, and any other small particles, helping maintain the quality of the final product.

Oil Clarification Challenges

As products containing various types of cannabis oil are projected to grow in popularity, small-scale extraction processing laboratories won’t be equipped to meet product demand. Removal of carbohydrates, fats, waxes, proteins and chlorophyll while refining the oil, has traditionally been accomplished using filtration methods such as Buchner funnels, bag filters and flat sheets. The challenges arising from these methods are:

- Small batch production (20L) and not scalable

- Large bottlenecks caused from step to step, for example flask, ethanol or filter paper changeouts

- Potential contamination risk with open air processing

- Unable to integrate into in-line processes with production or packaging lines

- Low yields resulting from drip loss

- Slow flowrates resulting in a temperature increase requiring multiple filtration passes

- Labor intensive installation and assembly

- Labor savings – reduced filter time and handling when compared to traditional methods

- Human mistakes minimized – e.g., breaking beakers that result in product loss.

- Increased product yield – Pall solutions allow for minimal losses through the use of an enclosed assembly.

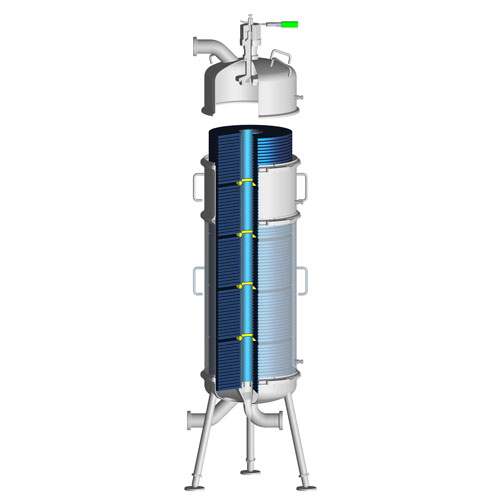

To meet the extract requirements and overcome the pitfalls of traditional methods, Pall worked with cannabis oil producers on an innovative solution utilizing SUPRA technology:

-

SUPRApak depth filter modules

-

SUPRAdisc™ II Filter Modules

-

Housings

To meet the extract requirements, Pall worked with cannabis oil producers on a new solution. An enclosed and sanitary system for filtering, SUPRApak technology utilizes a positive pressure push with no temperature increase. Available in surface areas ranging from 0.4 to 8 m2, SUPRApak modules provide the flexibility required for increased batch production.

Other benefits include:

- Our SLS – Global Technical Support Group is available to provide you with a broad range of support and process improvement recommendations.

- Significantly shortening time to filter waxes and unwanted lipids.

- High filtration capacity design, saving valuable production area.

- GMP and FCC compliant (subject to final test report), ensuring exceptional quality standards and peace of mind.

- Scalable, such that up to 6 SUPRApak modules can be vertically stacked, easily adding more surface area as your production grows.

Modular, such that several grades of media are offered for optimization of your specific fluid.

Our SUPRAdisc II modules are another enclosed sanitary system based on positive pressure enabling quick and easy filtration.

One advantage of the SUPRAdisc II format is its robust construction, making it an ideal option for higher viscous fluids such as winterized CO2 extract. Our SUPRAdisc II modules are available in a 12” and 16” format resulting in surface areas of 1.8 and 5 m2 respectively.

Other benefits:

- Back flushable for longer filter service

- Robust module design that can withstand reverse pressure shocks

- Separator plate construction to protect the filter media and facilitate easy module handling

- Modular, such that several grades of media are offered, enabling easy optimization for your specific fluid

- Our SLS – Global Technical Support Group is available to provide you with support for your specific needs and process improvement recommendations

- Shortened active filtration time to filter waxes and unwanted lipids

- High filtration capacity in a compact design, saving on space

GMP and FCC compliant (subject to final test report), helping to provide safe, effective products

Check Out for more Cannabis Oil filtration applications