Cider Producers Maximize Yield and Increase Quality With Our Cider and Perry Lees Solutions

Explore the Crossflow Filtration System Designed for Lees Processing

Lees, the sediment at the bottom of fermentation or maturation vessels, still contains a high percentage of recoverable cider. The OenoflowTM HS lees filtration system is a new crossflow filtration system designed specifically for recovery from lees.

This system overcomes the typical drawbacks associated with the existing Diatomaceous Earth (DE) based lees filters, producing higher quality product more efficiently and more economically.

Diatomaceous Earth (DE) filtration systems such as rotary vacuum drum filters (RVDF) and chamber press filters are the traditional methods used for filtering lees. While these systems can filter high solids effectively, the open design allows for oxygen pick up which can have a negative affect on quality. Recovered product often needs further processing and is typically downgraded in value and used in blends instead of added back to the original batch.

In many small and mid size cideries, the lees volume from a single batch is often too small for processing with DE based systems. In such cases, the cideries will delay processing the lees and wait to accumulate an appropriate volume. This delay leads to further reductions in quality, hence the potential to recover high value product is lost.

DE based technologies require large volumes of Diatomaceous Earth filter aid. This increases waste, disposal, labor, and losses; all factors contributing to high operating costs.

In more recent years, crossflow filtration is becoming the preferred choice of cidermakers for filtering lees because it overcomes the obstacles associated with traditional DE based technologies. Filtration is achieved with microporous membranes without the need for filter aids. With no powder handling and an enclosed system, operation is more hygienic and does not create DE waste for environmental landfill.

To Further Enhance Product Recovery the Oenoflow HS System Can Incorporate Diafiltration

Diafiltration

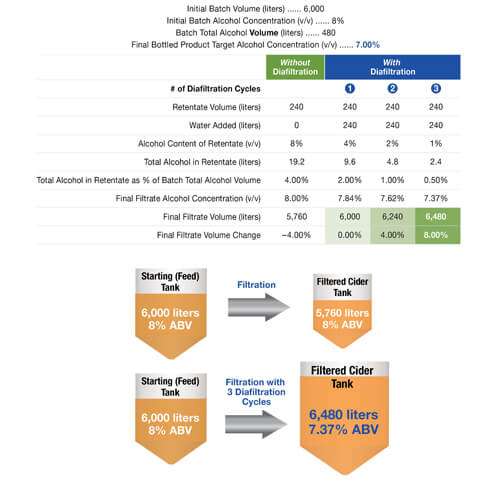

For customers that ferment to higher alcohol strengths and subsequently dilute to lower bottle strength, diafiltration can be used to significantly increase the final product yield.

During diafiltration water is added to the final retentate solids in the Oenoflow system to recover the alcohol that would otherwise be lost. This recovery increases yield and improves system ROI. Diafiltration is not typically performed on natural or traditional cider where the product is fermented only to bottle strength because the dilution would be unacceptable.

Ready to learn more? Contact us to speak an expert about the right cider filtration solution for you.

-

The Oenoflow HS Filtration System

Download: