Assuring Component Cleanliness is Best to Avoid System Failures

As fluid systems become more sophisticated and less tolerant to dirt, the controlling and measuring of component cleanliness has become a vital part of the manufacturing process. Every manufactured part potentially carries “built-in” contamination to the system.

Necessity of Component Cleanliness

In order to improve the life and reliability of fluid components used in the automotive, hydraulics and aerospace industries, the system and component cleanliness assembly need to be addressed. The measurement of components and parts cleanliness is related to contaminant collection, analysis and data reporting with ISO standards (International Organization for Standardization) continually being developed to control procedures.

Pall’s Component Cleanliness Management (CCM) solutions provide products and services for accurate, reliable, and repeatable component and fluid cleanliness measurement. The CCM program includes the supplies of cleanliness cabinets, cleanliness evaluations, specification development, and customized training, all undertaken in cooperation with our customers to optimize in-plant processes.

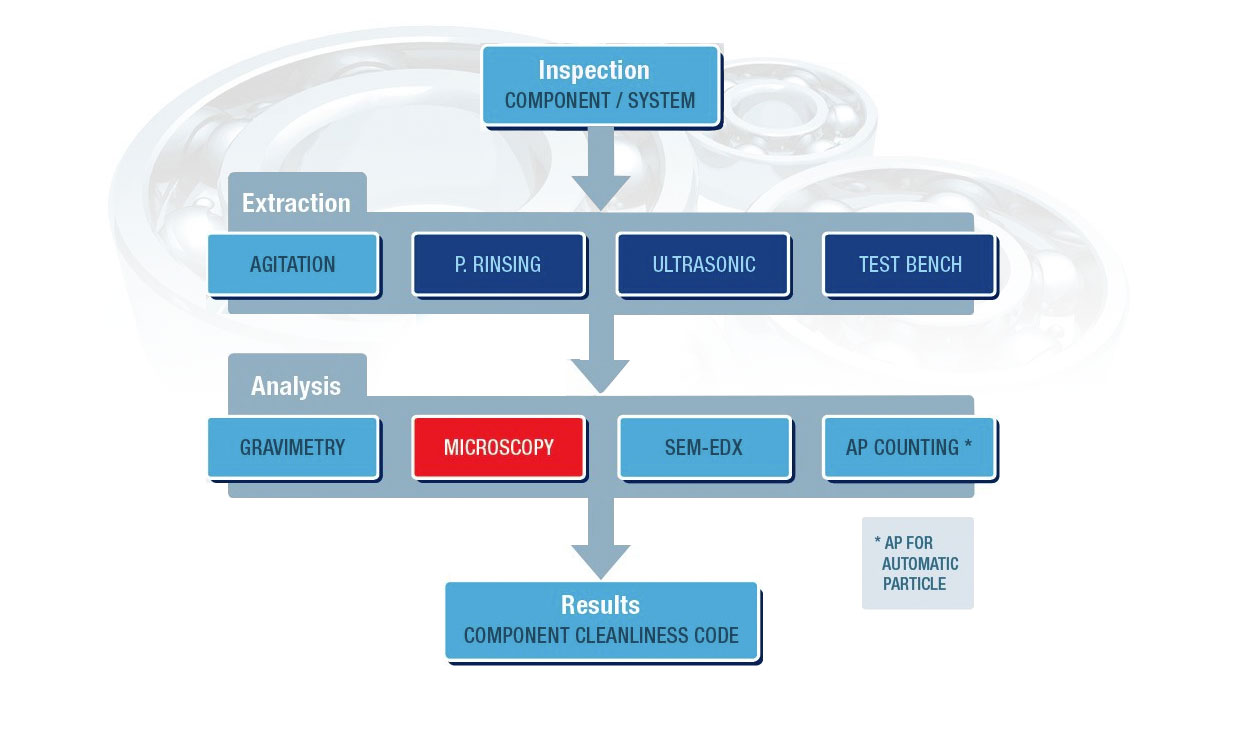

Process Flow Diagram of Component Cleanliness Process

For more information on improving the efficiency of your processes, contact our team of filtration experts.

Propelling service and support to the highest level

Pall can provide Annual Service Plans for existing users of Pall Cleanliness Cabinets. Available in different levels of support depending on your need or severity of equipment use, our service plans provide the assistance you need to protect your investment and optimize your workflow productivity. The plans represent cost savings when compared to purchasing repair, calibration or maintenance services individually. For more information, download the brochure in the Literature Library & contact our sales team for advice.

Pall’s Component Cleanliness Management (CCM) program provides products and services for accurate, reliable, and repeatable component and fluid cleanliness measurement.

The CCM program includes the supply of cleanliness cabinets, cleanliness evaluations, specification development, and customized training, all undertaken in cooperation with our customers to optimize in-plant processes.

Literature Library

For existing users of Pall Cleanliness Cabinets, please refer to the reference datasheets below for equipment specifications and spare parts

-

PCC Tech Facts datasheet.pdf

Download: -

Pall-Leica Capabilities

Download:

Our Products

Leading the Industry with product solutions that fit your customers needs.