Replacing a Blocked Filter Element

Sounds simple enough, but the reality can be quite different

With a new filter element in hand, the relevant tools and equipped with the correct PPE, the maintenance operator locates the blocked filter.

The work environment maybe poorly lit, hot, in an awkward or elevated location. The filter assembly itself maybe hot (from the service fluid passing through it), dirty and subject to a complete machine shutdown to carry out the filter element change.

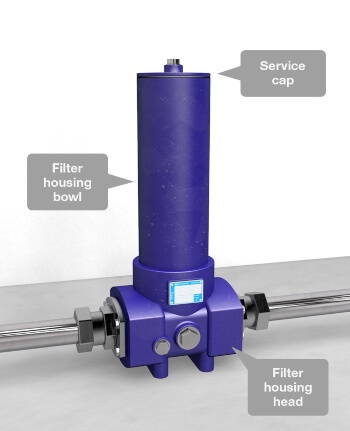

The task in hand is to depressurize the system, drain and capture the volume of service fluid held in the filter, unscrew the filter bowl to drop the bowl from the head assembly (potentially a 2-person task depending on filter size), remove and replace the blocked filter element and reverse the process to bring services back on line.

The traditional downward facing filter bowl is now replaced with an upward facing tube with an integral service cap. Once depressurized, just a small volume of service fluid needs to be drained. The easy to access filter cap, weighing just a few pounds (kilo’s) on even the largest of filters and significantly less than the previous bowl design, is unscrewed to access and replace the filter element.

There is a significant reduction in the risk of injury compared to previously needing to catch the bowl as it detached from the fine screw thread holding it in the head.

Service is achieved safely, without excessive weight risk to the operator, is 5 x quicker and with minimal loss of service fluid. The cap service filter has reduced operations Health and Safety risk rating by 54%.

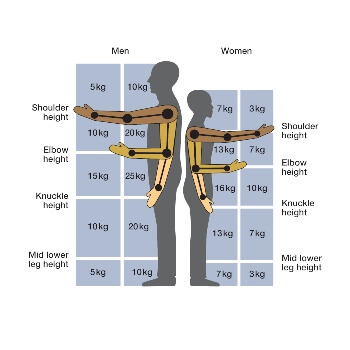

Employers have a legal obligation to protect the welfare of staff tasked with operating and maintaining their equipment. The Health and Safety Executive provides guidance on what is reasonably acceptable for personnel to lift and what body position they hold to do it, therefore it is important to appreciate the physical conditions and location of the filter and whether it is compliant. Whether an existing fitment or a new requirement, the Pall Athalon cap service filter design will protect operators from risk of injury and help employers improve the welfare of their staff.

Many industries have already approached Pall to convert their filtration systems to Athalon’s cap service design. If you would like to do the same, complete the form to left and we will be in return contact to help.

In the meantime, checkout the video above - Pall’s Tim Wright demonstrates the ‘then’ and ‘now’ of filter design and the impact it has on operator safety. Download our flyer to learn more.