Refineries are a complex industrial sector where HSEMS (Health, Safety and Environmental Management Systems) are vital. They define the principles of operation and control the risks throughout the processing lines. Since the "Zero Accident" culture began to incorporate the environment and, specifically, the level of CO2 emissions into the atmosphere in the past decade, the challenge is combining operational performance with safety.

The industry’s adoption of more stringent restrictions concerning environmental safety does not always mean increased costs in the medium to long term. It can even provide a short-term opportunity for improving the overall efficiency of a process, as demonstrated in a refinery operating in Southern Europe. See below the challenge, solution and result in this success story.

-

Challenge

-

Solution

-

Results

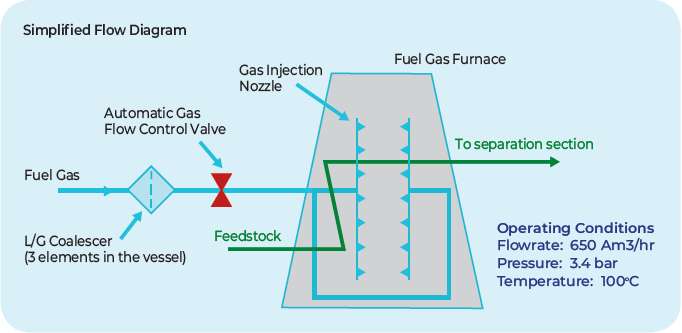

An automatic gas flow control valve installed upstream of the furnace was not operating well due to a very high level of solid and liquid contamination damaging the gas injection nozzles. This situation impacted the reliability, performance, and safety of the entire process.

The on-site team identified contamination as the root cause of the mechanical issues the flow control valve was facing.

They proposed installing a filter to remove particulate from the fuel gas stream to increase the energy efficiency of the furnaces of their reformer unit. Pall recommended the installation of a liquid/gas coalescer.

To validate the liquid/gas coalescer solution, the customer agreed to install a rental skid on its processing lines. This solution was also the most flexible and timely to implement corrective actions on the fuel gas stream.

The rental skid, a single-stage Seprasol Plus liquid/gas coalescer assembly, was installed in the fuel gas line, close to the automatic control valve, commissioned, and fully operational within two weeks.

Three months after installation, the coalescer ran without any issues and maintenance on the fuel gas control valve was not required. The gas furnace is also now able to operate at full capacity.

The rental skid fitted with Pall Seprasol™ Plus coalescers enabled the refinery to significantly improve the reliability of the fuel gas control valve regulating the flow rate at the inlet of the furnace. The installation of this skid not only reduces the cost of recurrent maintenance operations (dividing the OPEX budget of gas injection nozzles by two), but also increases the reliability, safety, and combustion efficiency of the furnace and provides added protection for downstream equipment. In addition, the refinery has reduced its CO2 emissions, contributing to the global effort to combat climate change. The customer plans to install a permanent solution and apply the same in another Fuel Gas line feeding the furnaces of a hydrodesulfurization unit.