Keep up to date with the latest filtration solutions for power generation markets

Your Integrated filtration and separation partner in Power Generation

Since 1946, Pall has been a leader in fluid purification technologies for the power generation industry. Our advanced separation technologies and high quality manufacturing provide filtration solutions for all power plant fluids, ensuring cleaner, safer, more reliable power with higher profitability. We offer filter housings, replacement elements, monitoring and turnkey systems for any size of application, from small flows and simple installations to large flows and complex systems.

Explore Low Carbon Power Generation Products, Systems and Solutions

Explore Our Solutions in Traditional Power Generation

Filter Rental Services

A locally available fleet of mobile equipment for short and long-term rental to protect critical process assets, safeguard output and improve product quality.

Featured products for various filtration applications

-

Hydraulic & Lubrication Filtration

-

Oil Purifiers

-

Varnish Removal in Oil Systems

-

Fluid Condition Monitoring

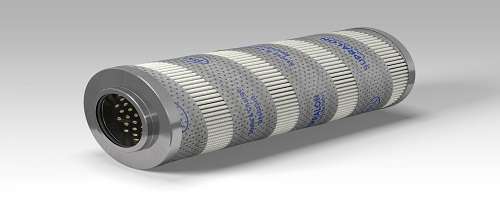

Athalon™ Filters

The Ultimate in Hydraulic & Lube Oil Filter Performance

Our easy to install Athalon™ pressure and return line housings contain filter elements made from inert, inorganic fibers in a coreless, Laid-Over Pleat (LOP) design configuration that maximizes the available filter capacity to extend filter service life. The filter element is resistant to high cyclic flow stress and dirt loading, has a Betax(c) ≥ 2000 efficiency rated (the highest rating in the industry today), and has anti-static properties to prevent the detrimental effects of electrostatic discharge. Athalon filter housings are also quick, safe, and easy to maintain by unscrewing the filter cap rather than removing the complete filter bowl.

Supralon Replacement Filter Elements

The direct replacement for existing Pall Coralon and Ultipor III filter elements and some alternative makes of filter housing

Water contamination promotes corrosion and fluid system component wear, resulting in reduced component life and increased maintenance costs. It also degrades fluid properties, leading to reduced lubricity and load carrying ability, oil oxidation and the resultant formation of acids, and additive precipitation. The consequences are reduced fluid service life and increased fluid procurement and disposal costs

Pall’s oil purification solutions remove 100% of free water 80% of dissolved water, they also remove 100% of free and entrained gases and up to 80% of dissolved gases.

Select the Pall oil purifier for:

- High performance water, gas and particulate removal

- Extension of fluid service life

- Minimized corrosion within systems

- Reduced fluid disposal

- Reduced operating costs

- Increased equipment reliability

- Simple automated operation

- Remote monitoring option

Watch the demonstration of dehydration technology associated with the HNP

Varnish is the thin, insoluble film deposit that forms on oil-wetted surfaces inside a turbine lube system, including bearings and servo valves. It’s formation is often attributed to higher operating temperatures, smaller fluid reservoirs, high cyclic service, and fluid base stocks that have lower solvency for varnish precursors.

You can’t see it, but you know it’s there taking your hydraulics system down one component at a time.

When varnish forms in turbine oils, the effects can be devastating to the operation and availability of the equipment, and may include:

- Sluggish controls and servo valves stiction, which can lead to expensive repairs or replacement

- Costly downtime from unscheduled outages

- Start-up delays from unresponsive control systems

The demand for reliability, availability, and seamless operation of today’s power turbines requires an efficient, easy and reliable method for removing varnish not only from the oil, but also from the wetted metal surfaces inside the machine

“You can’t manage what you can’t measure”

Pall monitoring solutions include fluid cleanliness monitors and filter condition indicators. Additionally, Pall in-line water sensors provide real-time measurement of dissolved water content in oils, warning of the potential formation of damaging free water in the gearbox and lube oil system. Pall can also apply years of accumulated knowledge to help translate raw data into meaningful information.