Contact a brewery specialist below.

Commercial Beer Filtration Systems

Discover the full potential of your brewing process with our innovative beer filtration systems

The Role of Filtration in Modern Brewing

Filtering beer is essential to meet the high standards required to preserve the brew’s unique taste, flavor purity and freshness. We provide advanced commercial beer filtration systems tailored to breweries of all sizes, from craft operations to global producers. Discover how breweries filter beer using our proven technologies that enhance clarity, flavor, and shelf life.

Filtering Beer for Quality, Consistency, and Shelf Stability

Beer quality is everything. Our advanced commercial beer filtration systems help breweries, from craft to global, achieve clarity, microbiological stability, and great taste. By filtering beer efficiently, you can extend shelf life, reduce waste, and optimize your brewing process.

Our solutions help breweries filter beer while cutting costs and supporting sustainability. With improved water efficiency, reduced contamination, and lower maintenance, you get consistent quality and streamlined operations.

Let’s talk about how Pall can help you improve your beer quality, reduce waste, and streamline your operations. Discover our effective solutions for every stage in the brewing process below.

Learn more about our beer IoT systems

Discover our brewery filtration solutions below:

Steps in Beer filtration process:

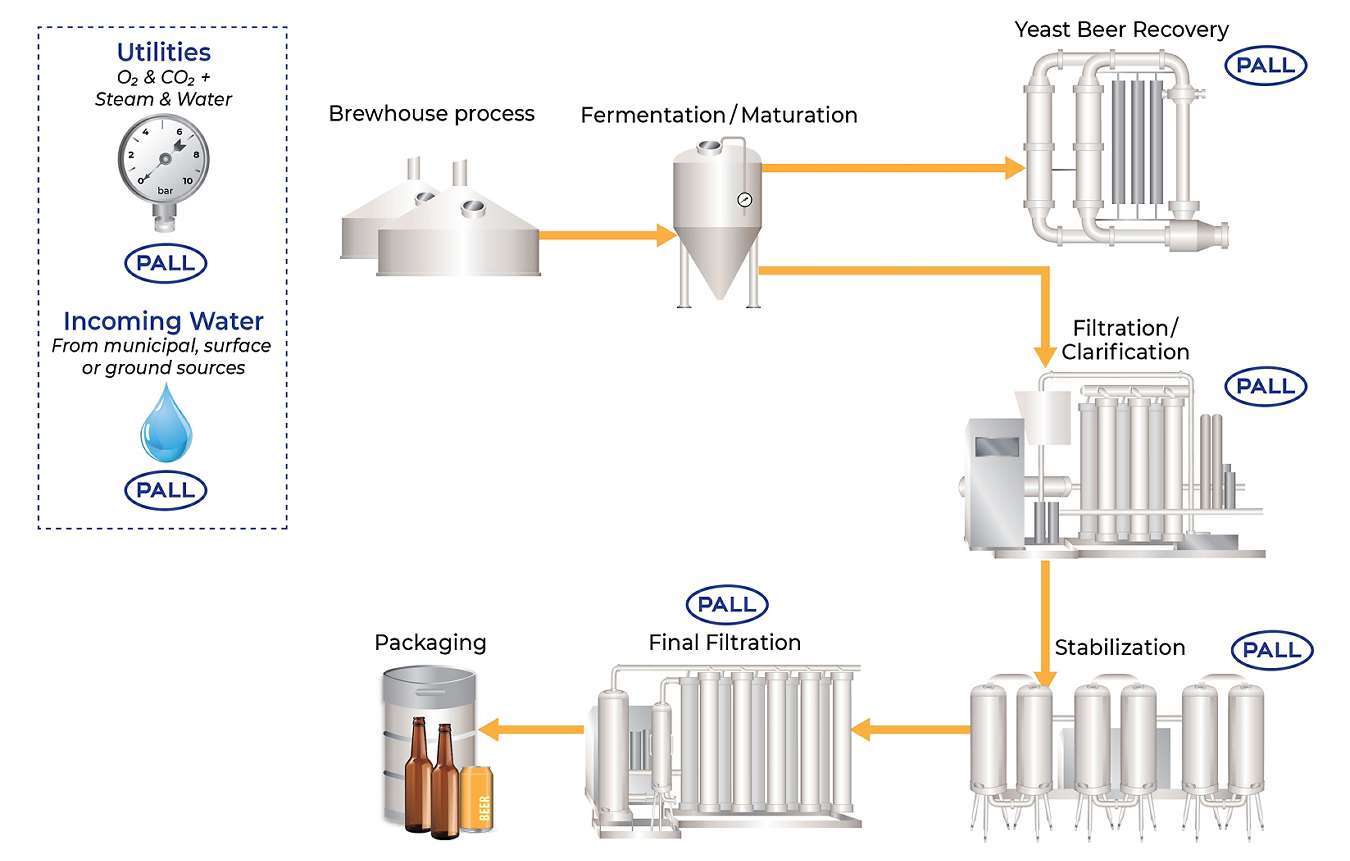

Pall Food & Beverage is the solution provider for the post fermentation process as shown in the diagram below.

Frequently Asked Questions

How do breweries filter beer?

Breweries filter beer through a multi-step process that includes clarification, microbial stabilization, and final filtration. These steps remove haze, yeast, and bacteria to ensure clarity, taste, and shelf stability.

What are commercial beer filtration systems?

Commercial beer filtration systems are industrial-grade technologies used by breweries to filter beer at scale. They remove unwanted particles while preserving flavor and ensuring safety.

Why is filtering beer important?

Filtering beer improves clarity, extends shelf life, and ensures a consistent taste experience. It’s essential for meeting consumer expectations and regulatory standards.

Resources