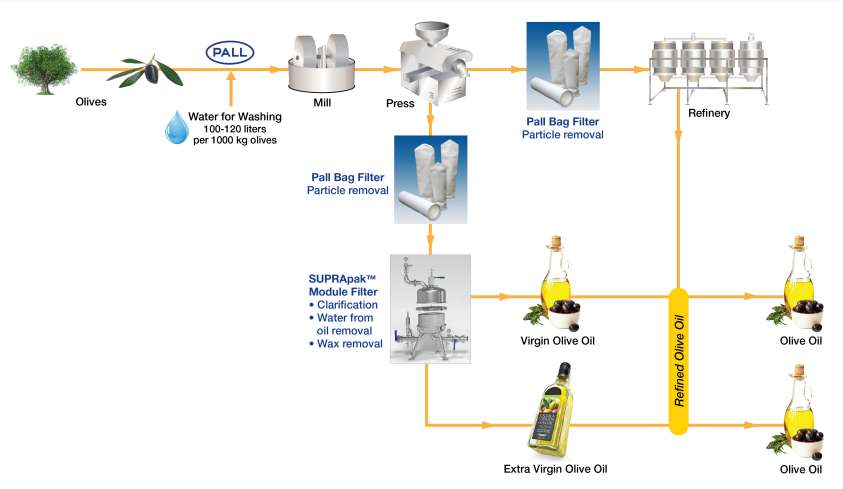

From Olives to Olive Oil

The production of olive oil has remained largely unchanged for centuries and is carried out exclusively with mechanical and not chemical processes. Ripe olives or olives that are about to ripen are ground immediately after the harvest in autumn with their kernels. The olive oil is then separated from the remaining skin, pulp and core by pressing or centrifuging. It is then essential that the olives are transported to the oil mill on the same day and processed the next day at the latest. Extra virgin olive oil (EVOO) is considered a food with a long shelf life. However, during storage EVOO undergoes several compositional changes that reduce its quality. If the olives are stored too long between harvest and pressing, unwanted fermentation processes start to work on the olive fruits which means it quickly loses its fresh, crunchy aroma, essentially degrading the quality of the final olive oil.