Improved Surface Finish and Reduced Rejection Rates

The visual appearance of cars is a crucial factor for a customer's purchase decisions. A consumer's first impression will come from the quality and consistency of the paint job and whether it meets their aesthetic demands. Even after a purchase, poor paint quality is the primary cause of client warranty complaints.

Customer expectations can be met through quality applications of a vehicle's finish. We offer a range of automotive paint filtration solutions built for the demands of OEM and Tier 1 suppliers. Our premium quality fine paint filtration elements will keep production moving. Built to withstand high flow rates and multiple shifts, they can keep defects due to contamination to zero.

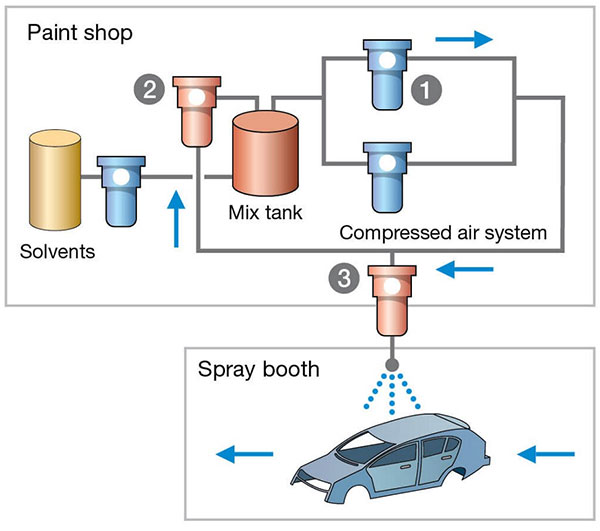

Four Pall product types should be considered in the paint shop:

Stage 1:

Profile II polypropylene filter cartridges or Nexis T series for the pressure line. Profile II is our premium product, while Nexis T filter cartridges can be more cost-effective because they can be considered for paint applications.

Stage 2:

Bag filters (size 4) for the return line, with NMO technology.

Stage 3:

PCF1YMAJ Profile II Filter capsules on the Point of Use

Depending on the paint quality and formulation (solvent or water-based), filter materials are different (Nylon filter cartridges or Polypropylene filter cartridges), while filter grades may be the same. This is usually discussed with the car maker and the paint formulator.

The benefits of using these solutions include:

- Controlled general system cleanliness whatever the paint formulation (water-based or solvent-based paint) or the coating layers (primer, top, clear coats)

- Reduced reject rates (better surface finish, fewer craters)

- Complete paint filtration coverage from the paint shop to the spray booth

Marksman – Cartridge/Bag Filters

Combining the performance of depth cartridge filters to the ease of use of bag filters, Marksman is designed to improve fluid quality while not adding to system complexity. Marksman is flexible and is offered in media including polypropylene, nylon, and glass, and customizable for specific applications. These filters also fit existing Size 1 and Size 2 bag housings making retrofitted upgrades easy.

As the Marksman operates similarly to a bag system, contaminants are kept trapped and upstream of the nozzle during replacement. The filter has enough built-in rigidity to eliminate the need for internal springs or guide plates.

Marksman offers improved cost and labor efficiencies as the high surface area, and long life of one filter can equal the performance life of up to 10 standard 25.4 cm / 10 in bag filters.

To learn how our automotive paint filtration solutions can fit and upgrade the performance of your paint and protective coating process, or to find out more about the products mentioned on this page, please contact a Pall expert using the contact us button.

For more information on improving the efficiency of your processes, contact our team of filtration experts.

Our Products

View our full range of industry leading product solutions that fit your customers needs.

Parts Washing

Component Cleanliness